Igwe eji akwa CNC Turret Punch dị elu

1. Single servo moto chụpụrụ usoro, adopts nnukwu torque kpọmkwem chụpụrụ servo moto na ụgbọala unit na elu ibu ibu ikike ịghọta ala ike oriri, elu nnyefe arụmọrụ, a pụrụ ịdabere na arụmọrụ na adaba mmezi.

(1) Mgbanwe ọsọ na ọrịa strok

a. Enwere ike ịhọrọ ọrịa strok dị ka ọkpụrụkpụ nke mpempe akwụkwọ ahụ na-akpaghị aka, na-emeziwanye arụmọrụ ọrụ.

b. A na-emegharị ọsọ ntụmadị n'oge ọ bụla n'otu ọdụ ọdụ ọ bụla,

c. igwe nwere ike ịghọta ngwa ngwa ngwa ngwa dị elu n'oge ịgba ọsọ efu na obere ọsọ n'oge ezigbo ntụmadị, n'ụzọ dị otú a, enwere ike ịkwalite àgwà ntụmadị nke ọma, ọ nweghịkwa mkpọtụ n'oge ọkpọ.

(2). Njirimara sistemu a nwere ngwaọrụ nchebe karịrị oke ugbu a yana ngwaọrụ nchekwa oke ibu.

(3). Enwere ike gbanwee ike ọkpọ ahụ na-akpaghị aka dị ka ọkpụrụkpụ mpempe akwụkwọ na ebule na-agba ọsọ iji mee ka àgwà ọkpọ ahụ ruo ọkwa dị elu.

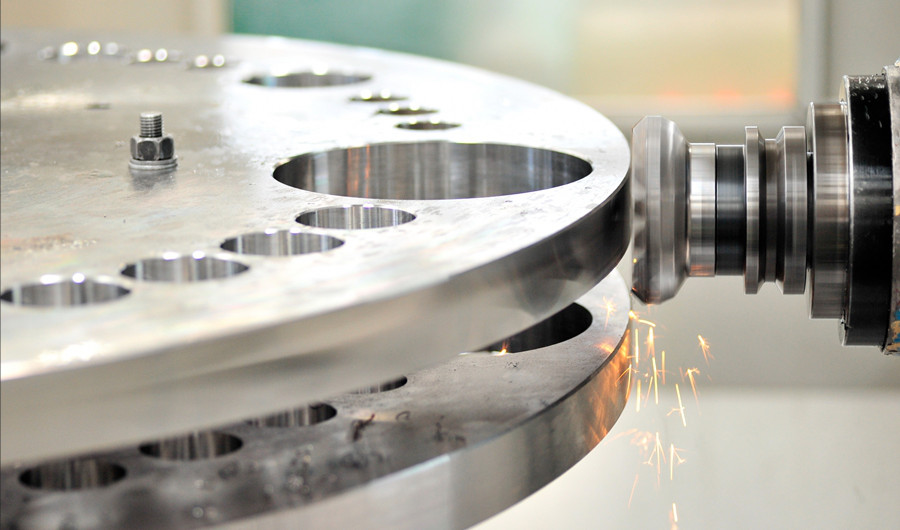

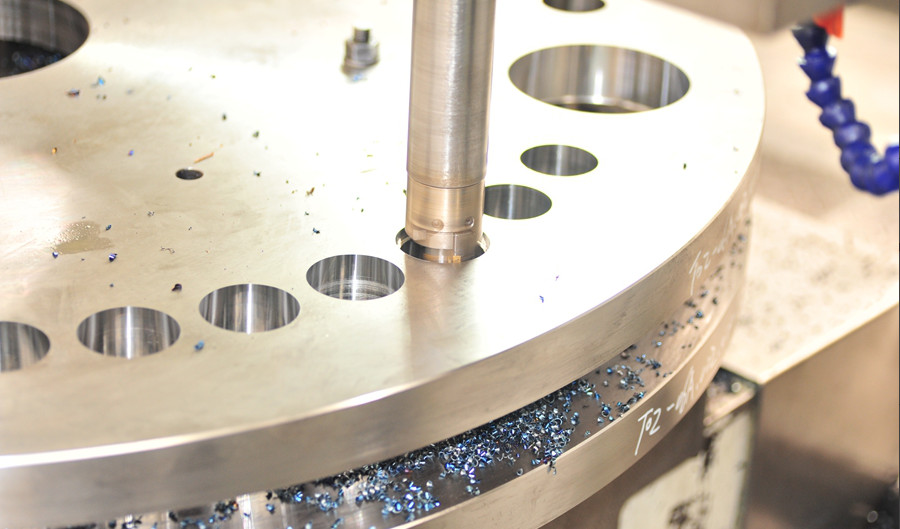

2. The turret na bushing bụ usoro na abụọ

A na-edozi turret site na ngwaọrụ pụrụ iche iji hụ na coaxial nke elu na elu turret na gbasaa ndụ ọrụ nke ngwá ọrụ; ahịhịa ahịhịa na-eme ka usoro turret dị mfe iji gbasaa ndụ ọrụ; Enwere ike iji ngwá ọrụ dị ogologo mee ka ọ dịkwuo mma na-eduzi ma gbasaa ndụ ọrụ ngwá ọrụ (maka nnukwu mpempe akwụkwọ).

3. Mbubata pneumatic, lubricating na eletriki eletrik na-eme ka ntụkwasị obi nke igwe dum.

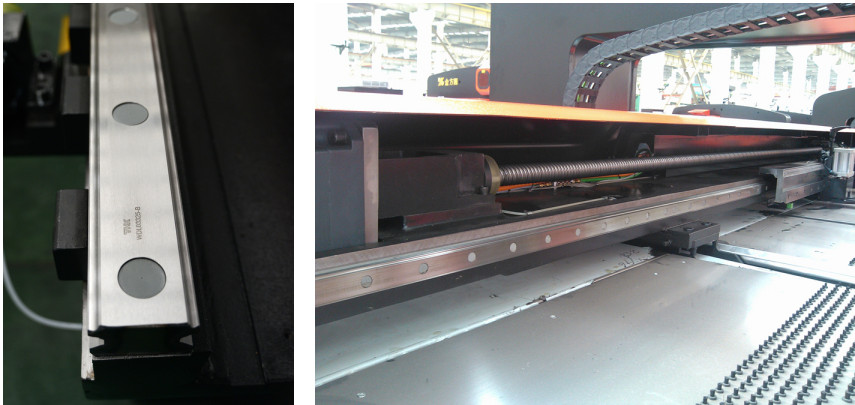

4. Nnukwu ụzọ ndu ụzọ na bọọlụ si Japan ma ọ bụ Germany na-ahụ maka nri dị elu nke ọma.

5. Ahịhịa siri ike na bọọlụ agwakọta worktable na-ebelata mkpọtụ na ịma jijiji n'oge na-agba ọsọ ma na-echekwa elu mpempe akwụkwọ.

6. O-ụdị welded etiti agbajiwo ugboro abụọ, ehichapụrụ nrụgide kpamkpam. A na-ahazi etiti ahụ site na Germany SHW dual-side pentahedron nhazi center n'otu oge, ọ dịghị mkpa ime ka oge nke abụọ ọnọdụ.

7. Mwekota na-ese n'elu mmiri na nnukwu njigide ike na-eme ka nri kwụsiri ike; ụgbọ ala agbakwunyere na-eme ka nkwụsi ike dị mma na mmegharị dị mma nke mwekota.

8. A na-egosipụta usoro ahụ na ọrụ nke nchebe mgbochi akpaka iji zere mmebi nke ngwá ọrụ na nkwụsịtụ, na-eme ka usoro ihe omume ahụ na-aga n'ihu.

9. The auto-index adopts elu ziri ezi worm wheel na worm usoro, n'ịhụ na elu kpọmkwem indexing. Nke Max. dayameta tooling nwere ike iru 88.9mm na akpaaka-index nwere ike gbasaa na 4 mba.

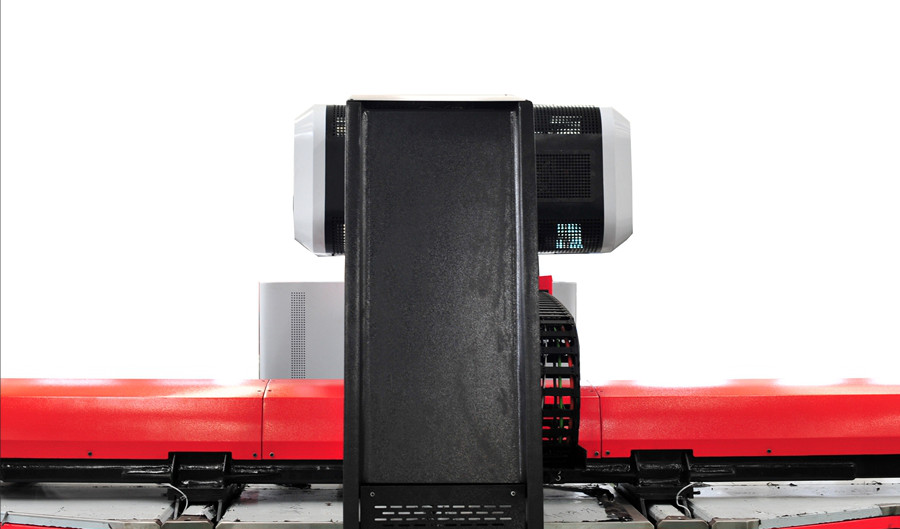

10. Integrated beam structure to make the cara and beam n'ime otu akụkụ, na-amụba siri ike ma na-eweta ọnọdụ ziri ezi. Igwe ahụ nwere ike na-agba ọsọ nke ọma n'oge nri dị elu ma ọ na-eme ka njedebe nke axes X na Y kwụsị.

11. X axis: adopts servo moto ụgbọala na elu kpomkwem bọọlụ ndị ọrụ na ihe na-ebu na-agba na elu rigidity na fechaa imewe. Y axis: servo moto na-ebugharị ngwa nri nri nke ejikọtara ya na ụzọ igwe, a na-edozi ụdị beam na nri nri, a ga-ebunye ike na-arụ ọrụ na igwe igwe & ala site na nri nri na ụzọ ụzọ iji belata ịma jijiji nke onwe. A na-egosipụta ihe owuwu a na njirimara nke ịdị mma siri ike, ịdị arọ dị arọ, ike ndọda dị ala, na nzaghachi dị ike na usoro nri dum, ịgba ọsọ kwụsiri ike na nke ziri ezi.

12. Central lubrication usoro na-anakwere izipu lubrication griiz na ikwu lubricating ebe ozugbo, mbenata esemokwu nke ọ bụla na-arụ ọrụ ụzọ abụọ na-amụba ndụ ọrụ.

13. Mgbochi mpempe akwụkwọ-deformation mgba ọkụ na mpempe akwụkwọ-mgbochi-stripping mgba ọkụ na-nakweere.

| Mba. | Aha | Qty. | kwuo |

| 1 | Ndepụta nkwakọ ihe | 1 set | |

| 2 | Asambodo ogo | 1 set | |

| 3 | Akwụkwọ ntuziaka maka igwe | 1 set | |

| 4 | Akwụkwọ ntuziaka ọrụ eletrik | 1 set | |

| 5 | Ihe osise ntọala | 1 set | |

| 6 | Ihe osise Eletriki | 1 set | |

| 7 | Akwụkwọ sistemu ngwanrọ akpaaka | 1 set | |

| 8 | DBN Eletriki Isi Ihe osise | 1 set | |

| 9 | Akwụkwọ ntuziaka ngwaọrụ | 1 set | |

| 10 | Akwụkwọ ntuziaka CNC | 1 set | |

| 11 | Ịse Ihe Ngwá Ọrụ | 1 set |

| Mba. | Aha | Nlele | Qty. |

| 1 | Spanner dual-head | 5.5 × 7-22 × 24 | 1 set |

| 2 | Spanner enwere ike ibugharị | 200 | 1 mba. |

| 3 | Socket Head Spanner | S1.5-S10 | 1 set |

| 4 | Cross screwdriver | 100×6 | 1 mba. |

| 5 | Egbe mmanụ aṅụ | HS87-4Q | 1 mba. |

| 6 | Egbe mmanu mmanu mmanu | SJD-50Z | 1 mba. |

| 7 | Egbe nrụgide dị elu | 1 set | |

| 8 | T shape isi | M14 × 1.5 | 1 mba. |

| 9 | Mgbanwe nso | M12 PNP SN=2 mepere | 1 set |

| 10 | Mgbanwe nso | M12 PNP SN=2 nso | 1 mba. |

| 11 | Spanner | T09-02,500,000-38 | 1 mba. |

| 12 | Spanner maka gas cylinder mgba ọkụ | 1 set | |

| 13 | Ọkụ dị nro | Ø 12 | 1 mba. |

| 14 | Ntụtụ ọkpọkọ dị nro | KQ2H12-03AS | 1 set |

| 15 | Akụkụ ntọala | 1 mba. |

| Mba. | Aha | Nlele | Qty. | kwuo |

| 1 | Mwekota gia osisi | 3 mba. | T02-20A.000.000-10C T02-20A.000.000-24A | |

| Machie osisi portective | 6 mba. | T02-20A.000.000-09C Ma ọ bụ T02-20A.000.000-23A | ||

| 2 | Mmiri Obere ịghasa na mwekota | M4x10 | 20 mba. | T02-06,001,000-02 |

| M5x12 | ||||

| 3 | ịghasa na mwekota N'ime ịghasa | M8 x 1 x 20 | 20 mba. | |

| 4 | Akpụkpọ anụ | 30T | 2 no. | T09-16.310,000-0.1.2 |

| 5 | Ntugharị ime | M8 x 1 x 20 | 4 mba. |

Usoro FANUC CNC bụ usoro CNC pụrụ iche nke Japan FANUC mepụtara karịsịa maka nzube nke izute atụmatụ nke ụdị igwe a, na-eme ka ntụkwasị obi nke igwe ahụ dịkwuo ukwuu.

I, Njirimara sistemu

1. Ọrụ eserese na ọkpọ;

2. Usoro koodu G nke zuru ụwa ọnụ maka ịrụ ọrụ dị mfe;

3. Universal RS232 ọkọlọtọ ọdụ ụgbọ mmiri na-ekwurịta okwu na kọmputa na-adaba adaba;

4. Di elu zuru ezu dijitalụ servo moto na servo usoro;

5.10.4 ″ LCD ngosi ngosi;

6. Pulse encoder ọkara loop nzaghachi;

7. Ebe nchekwa EMS: 256K;

8. Mmemme ubi, mmemme ụlọ ọrụ;

9. Ihe ngosi China na Bekee;

10. Ọrụ nke simulation eserese;

11.One nnukwu ikike PCMCIA kaadị maka ndabere nke usoro oke, ubube ịbịaru na nhazi usoro, na-aghọta online usoro nke nnukwu ikike nhazi usoro;

12. Mmụba na nke kacha nta, ọnọdụ nchọpụta ad servo akara na-aghọta elu na-agba na elu ezi ọrụ;

13. Enwere ike ịkọwa bọtịnụ ọrụ na panel dị ka ezigbo ihe achọrọ;

14. Super elu ọsọ clutch data cables na obere eriri njikọ;

15. Njikọ dị elu, ngwanrọ pụrụ iche. Oge dị mkpirikpi maka mmalite, data agaghị efu ma ọ bụrụ na ike adịghị abịa na mberede;

16. Nchekwa nke 400 iberibe mmemme.

1. Anyụike ahịrị: X, Y axes, anyụike na-atụgharị: T, C axes, axis axis: axis Z;

2. Mkpu maka njehie eletrik dị ka oke-strok.

3. Ọrụ nyocha nke onwe.

4. Ọrụ nke oke nro.

5. Universal G koodu maka mmemme;

6. Ọrụ nke ịkwụ ụgwọ ngwá ọrụ;

7. Ọrụ nke ịghasa anya ụgwọ;

8. Ọrụ nke nkwụghachi ụgwọ ọdịiche;

9. Ọrụ nke nhazi nhazi;

10. Ọrụ nke reposition;

11. Ọrụ nke AUTO, akwụkwọ ntuziaka, ọnọdụ JOG;

12. Ọrụ nke mgbochi mgbochi;

13. Ọrụ nke mkpọchi nke ndekọ n'ime;

14. Ọrụ nke mmemme parameter;

15. Ọrụ nke sub-program;

16. Ọrụ nke itinye ngwa ngwa na mkpọchi ọkpọ;

18. Ọrụ nke koodu M;

19. Usoro zuru oke na mmụba;

20. Conditioning, unconditioning jump.

Iwebata ngwanrọ mmemme

Anyị na-enweta CNCKAD sitere na ụlọ ọrụ METALIX. Akụrụngwa bụ sọftụwia mmemme akpaaka CAD/CAM zuru oke site na imewe ruo na mmepụta. Site na njikwa ọba akwụkwọ ebu, nhazi nhọrọ ọnọdụ akpaka, njikarịcha ụzọ na ọrụ ndị ọzọ, enwere ike imepụta ya na-akpaghị aka site na usoro nhazi CAD ịbịaru NC. Ị nwere ike nweta otu akụkụ mmemme, akpaka nesting na zuru ezu ngwugwu.

Ọrụ nke DrawingCNCKAD dị ike ndịna-emeputa, dị mfe na kensinammuo iji, na mgbakwunye na nke ọkọlọtọ osise ọrụ dị ka e ji mara nke mpempe akwụkwọ metal, kwukwara ụfọdụ pụrụ iche ịbịaru ụzọ dị ka mbepụ, gburugburu, triangle, nri angle na contour udi, igwakorita, ịlele edezi na akpaka mgbazi, ịkpụ ma ọ bụ stamping, Chinese odide DXF/IGES/CADL/DWG faịlụ ntinye wdg

b) Ọrụ ịkụ ọkpọ

Ejiri ya na ntụmadị akpaaka, ebu pụrụ iche, ntụnye akpaaka, mbugharị akpaaka, mbelata ọnụ, na ọrụ ndị ọzọ.

c) Ọrụ nke Shearing

Nyochaa ihe nleba anya na-akpaghị aka ma mezie paramita nke ụdị ihe ahụ, ọkpụrụkpụ, otu ịkpụ, ịkpụ, na ịkwagharị akwagharị, na ọrụ ndị ọzọ, efere mmejuputa iwu nhazi nhazi.

d) Nhazi nhazi

Nhazi akpaaka ma ọ bụ mmekọrịta na-ekpuchi usoro niile: stampụ, laser, plasma, ọkụ, ịkpụ mmiri na igwe igwe.

Nhazi ọkwa dị elu nwere ike ịmepụta ụdị koodu NC dị irè, nkwado subroutine, mmemme nnukwu, dị ka njikarịcha ụzọ ngwá ọrụ na ntụgharị obere ebu, ntụtụ nkwado, igwe na-ekpo ọkụ na-arụ ọrụ dị ka ihe onwunwe na ọnụego nkwụsịtụ.

Mmemme mbufe gaa na igwe ọzọ dị mkpa naanị pịa ole na ole site na òké. A na-enweta ihe ndị a site na usoro nhazi CNCKAD, site na iwepu faịlụ kọmpụta gabigara ókè nke na-eme ka ọrụ ahụ dịkwuo mma.

e) CNC eserese eserese

Ngwanrọ na-akwado ịme anwansị eserese ọ bụla nke mmemme CNC, gụnyere koodu CNC ejiri aka dee, usoro ndezi dịkwa mfe, sọftụwia nwere ike lelee njehie na-akpaghị aka, dị ka mpịachi furu efu na njehie anya, wdg.

f) Ngbanwe site na NC gaa na Drawing

Ma ọ bụ aka edere ma ọ bụ koodu NC ọzọ, enwere ike ịgbanwe ya na eserese akụkụ.

g) Akụkọ ụbọchị

Nwere ike ibipụta akụkọ data, gụnyere ozi niile dị ka ọnụ ọgụgụ akụkụ, hazie ozi dị ka oge, nhazi ihe wdg.

h) Nbufe DNC

Ịnabata Windows interface nke modul nnyefe, nke mere na nnyefe n'etiti PC na akụrụngwa dị nnọọ mfe.

1) Kwado ugbu a niile ụdị nke CNC turret Punch, laser ọnwụ igwe, plasma ọnwụ igwe na ire ọkụ ọnwụ igwe na ndị ọzọ na igwe ngwaọrụ.

2) Nkwado dum usoro nke CNC ngwá ọrụ, gụnyere ịbịaru, akpaka ma ọ bụ mmekọrịta nhazi, post nhazi, CNC ịme anwansị omume, akwụkwọ ntuziaka na akpaka ọnwụ, NC faịlụ download na bulite wdg.

3) Nwere ike itinye Autocad ozugbo, SolidEdge, SolidWork na CadKey wdg gụnyere faịlụ eserese CAD niile ama ama emepụtara.

4)、Software akwado a dịgasị iche iche nke dị iche iche numerical akara akụrụngwa, nwere ike na-etinye a NC akụkụ n'ịwa dị iche iche ngwá faịlụ, n'ihi na otutu ngwaọrụ n'otu oge n'oge nhazi.

Ndokwa akpaaka

Mgbe nha efere dị ukwuu karịa ebe ụfọdụ, igwe ahụ na-edobe ya na-akpaghị aka, wee mepụta ntuziaka n'ọnọdụ ọnọdụ na-akpaghị aka; ọ bụrụ na onye ọrụ nwere ihe pụrụ iche chọrọ, nwere ike gbanwee ma ọ bụ ihichapụ na ha re n'ọnọdu ntụziaka.

Mwepu mkpọchi akpaaka

Ntuziaka na-emepụta site na ntinye na-akpaghị aka nke nwere ike ime ka njide na-ezere mpaghara nwụrụ anwụ, belata ihe mkpofu; ma a efere bụ akụkụ ma ọ bụ ọtụtụ akụkụ nke a ígwè efere, nwere ike na-aghọta mwekota zere ọrụ.

Nhazi ihe mgbawa

Iji belata nrụrụ nke ihe na stampụ usoro, a pụrụ ịnakwere usoro nhazi ihe mpempe akwụkwọ, a pụkwara iji ngwá ọrụ ịkpụ n'ihu ma ọ bụ azụ nke ntụziaka alaka.

Usoro ịkwachaa

Ejikọtara ya na ọrụ nke ịkụ ọkpọ nkịtị, ịkụ ọkpọ akpaka nke na-enwe ike ịkụ ọkpọ ihe gbajiri agbaji n'akụkụ ọnụ.

Otu jụụ na-aga na-akpaghị aka

Enwere ike iji igwe mwekota ibughari site na ngwanro na-akpụ akpụ mkpọ na-akpaghị aka site na ntuziaka NC.

Obere anwụ ntụgharị

Nhọrọ ntụgharị ọnwụ kacha nta nwere ike ibelata iyi nke ọdụ ntinye aka na-akpaghị aka ma melite arụmọrụ mmepụta.

Ọrụ nke ụdị Punch ọzọ

Ọrụ nke ịkụ ọkpọ triangle, ịkụ ọkpọ, ịkụ ọkpọ na ụzọ ịkụ ọkpọ ndị ọzọ pụrụ iche na nke ọma.

Ọrụ nke Ịgba akpaaka siri ike

Njirimara Punching akpaaka gụnyere njikọ micro na akpaaka, nhọrọ nwere ọgụgụ isi nke ebu na ụbara nchọpụta mkpu na ọrụ ndị ọzọ.

I) Ọrụ ịkpụ akpaaka

METALIX CNCKAD nwere akụrụngwa AutoNest nke bụ sọftụwia na-ebuli ngwa ngwa ngwa ngwa ngwa ngwa, nke nwere ike ịghọta njikarịcha nchara nke usoro nka.

1. Ikuku ikuku: gosiri na nrụgide ọrụ kwesịrị ịbụ karịa 0.6mPa, ikuku ikuku: karịa 0.3m3 / min

2. Ike: 380V, 50HZ, ike fluctuate: ± 5%, eletriki ike nke 30T bụ 45KVA, na ike USB dayameta bụ 25mm², emebi bụ 100A. Ọ bụrụ na ọkụ eletrik adịghị eguzosi ike, a chọrọ stabilizer, ọ bụrụ na enwere ọkụ eletrik, a chọrọ nchebe.

3.Hydraulic mmanụ: (SHELL) Tonna T220, Ma ọ bụ ọzọ mmanụ maka ndu na ụgbọ okporo ígwè lubrication.

mmanu mmanu: 00#-0 # oke udi griiz (GB7323-94), aro: n'okpuru 20 Celsius iji 00 # oke nrụgide griiz, n'elu 21°C were 0# Oke nrụgide griiz

| Ụdị | Aha | Okwu | Okpomọkụ |

| Shell | EPO | 0# Oke mmanu mmanu | 21°C n'elu |

| Shell | GL00 | 00# Oke mmanu mmanu | 20 Celsius C n'okpuru |

3. Okpomọkụ gburugburu: 0°C - +40°C

4. Iru mmiri gburugburu: iru iru mmiri 20-80% RH(un-condensation)

5. Chebe na ịma jijiji siri ike ma ọ bụ igbochi electromagnetism

6. Gburugburu na obere uzuzu, enweghị gas na-egbu egbu

7. Kwadebe ihe mgbakwasị ụkwụ dịka eserese ntọala

8. Onye ọrụ ga-ahọrọ technician ma ọ bụ engineer maka ọzụzụ, agụmakwụkwọ ndabere nke kwesịrị dịkarịa ala gụsịrị akwụkwọ na teknuzu secondary school, ma hazie ya maka ogologo okwu.

11.Must ga-akwadebe ntọala dịka eserese ahụ

12. A oghere 65mm spanner wrench, mkpanaka na-akwado afterburner, iji dozie ọkwa ntọala.

13. Ihe karịrị lita 5 nke mmanụ ụgbọala dị ọcha, ọnụ ọgụgụ nke akwa akwa, egbe, mmanụ mmanụ, ihe dị ka 1 lita maka ihe eji eme ihe na-ekpocha ihe na ihe ọkpụkpụ.

14 nwere otu Ф10 * 300 na otu Ф16 * 300 mkpanaka ọla kọpa maka nrụnye ebu. Ogologo ogologo (fuselage na beam na-achịkọta iche iche, kamakwa iji dozie nkeji ndị ahụ)

15 ihe ngosi ọkpụkpọ (oke 0-10mm), nke a na-eji emezigharị axis X na Y perpendicularity.

16 mgbe akụrụngwa ruru ụlọ ọrụ mmepụta ihe, dozie okporo ụzọ 20T ma ọ bụ kreen maka ebuli akụrụngwa

17.If V axis na-onwem na mmiri chiller moto, metụtara jụrụ median ga-adị njikere, olu bụ 38L.

Ihe ndị ọzọ anaghị ekpuchi ya chọrọ nkọwa na nhazi ọzọ

Igwe ihe eji eme ihe eji eme ihe; igwe ihe eji eme ihe; igwe ihe eji eme ihe; Igwe ihe nrịbama; cnc ịkụ ọkpọ na igwe na-ehulata; ọnụọgụ njikwa turret punch press;servo drive turret punch press; turret punch press for sale

| Mba. | Nkọwapụta | Nkeji | Ụdị igwe | ||

| MT300E | |||||

| 1 | Oke. Punch Force | kN | 300 | ||

| 2 | Ụdị ịkwọ ụgbọala isi | / | Otu moto na-anya | ||

| 3 | Sistemụ CNC | / | FANUC CNC usoro | ||

| 4 | Oke. Nha Nhazi mpempe akwụkwọ | mm | 1250*5000 (ya na otu nrụzigharị) | 1500*5000 (ya na otu nrụzigharị) | |

| 5 | Nọmba nke Mgbochi | mba. | 3 | ||

| 6 | Oke. Mpempe akwụkwọ nhazi | mm | 3.2 / 6.35 | ||

| 7 | Oke. Punch dayameta kwa oge | mm | Φ88,9 | ||

| 8 | Isi Striker Stroke | mm | 32 | ||

| 9 | Oke. Punch kụrụ na 1mm Pace | hpm | 780 | ||

| 10 | Oke. Punch Hot na 25mm ijeụkwụ | hpm | 400 | ||

| 11 | Oke. Ịgba ọsọ | hpm | 1800 | ||

| 12 | Mba. nke Ndozi Silinder | setịpụrụ | 2 | ||

| 13 | Nọmba ọdụ ụgbọ mmiri | mba. | 32 | ||

| 14 | Nọmba nke AI | mba. | 2 | ||

| 15 | Nọmba nke Axis njikwa | mba. | 5 (X, Y, V, T, C) | ||

| 16 | Ụdị Ngwá Ọrụ | / | Ụdị Ogologo | ||

| 17 | Ụdị arụ ọrụ | / | N'okpuru 3.2mm: Mpempe ahịhịa zuru ezu edoziri worktable (Enwere ike ịgbakwunye bọọlụ na-ebuli maka ibu dị ka nhọrọ) | ||

| N'elu 3.2mm: Bọọlụ zuru ezu na-arụ ọrụ | |||||

| 18 | Oke. Ọsọ inye nri | Axis X | m/min | 80 | |

| Y Axis | 60 | ||||

| Ejikọtara XY | 100 | ||||

| 19 | Turret Speed | rpm | 30 | ||

| 20 | Ọsọ ntụgharị ngwaọrụ | rpm | 60 | ||

| 21 | izi ezi | mm | ±0.1 | ||

| 22 | Oke. Ibu Ibu | Kg | 100/150 maka bọọlụ na-arụ ọrụ | ||

| 23 | Isi ike moto | kVA | 45 | ||

| 24 | Ụdị ngwá ọrụ | / | ụdị disssembly ngwa ngwa kwụpụrụ onwe ya | ||

| 25 | Nrụgide ikuku | MPa | 0.55 | ||

| 26 | Oriri ikuku | L/min | 250 | ||

| 27 | Ike ebe nchekwa CNC | / | 512k | ||

| 28 | Nchọpụta mpaghara nwụrụ anwụ | / | Y | ||

| 29 | Mpempe akwụkwọ mgbochi mgbochi mgbanaka | / | Y | ||

| 30 | Mgbanwe Mgbochi mpempe akwụkwọ-Deformation | / | Y | ||

| 31 | Ngosipụta nkọwapụta | mm | 5350×5200×2360 | 5850×5200×2360 | |

| Mba. | Aha | Ụdị | Nlele | ||

| 1 | Sistemụ CNC | FANUC | OI-PF | ||

| 2 | Onye ọkwọ ụgbọ ala Servo | FANUC | AISV | ||

| 3 | Servo moto (axis X/Y/C/T) | FANUC | AIS (X, Y, T, C) Moto pụrụ iche maka axis V | ||

| 4 | Ụzọ nduzi | THK | HSR35A6SSC0+4200L (X:2500) | ||

| HSR35A3SSC1+2060L-Ⅱ (Y:1250) | |||||

| HSR35A3SSC1+2310L-Ⅱ (Y:1500) | |||||

| 5 | Ihe mkpuchi bọọlụ | THK | BLK4040-3.6G0+3016LC7 (X:2500) | ||

| BLK3232-7.2ZZ+1735LC7T (Y:1250) | |||||

| BLK3232-7.2ZZ+1985LC7T (Y:1500) | |||||

| 6 | Ngosipụta nke ọma | NSK/Koyo | 25TAC62BDFC10PN7B/SAC2562BDFMGP4Z | ||

| 30TAC62BDFC10PN7B/SAC3062BDFMGP4Z | |||||

| 7 | Akụkụ pneumatic | Njikọ atọ | SMC | AC30A-03D | |

| Solenoid valvụ | SY5120-5D-01 | ||||

| Muffler | AN10-01 | ||||

| Silinda | CP96SDB40-80-A93L | ||||

| 8 | Sistemụ eletriki | Njiji | Schneider | / | |

| Kpọtụrụ | Schneider | / | |||